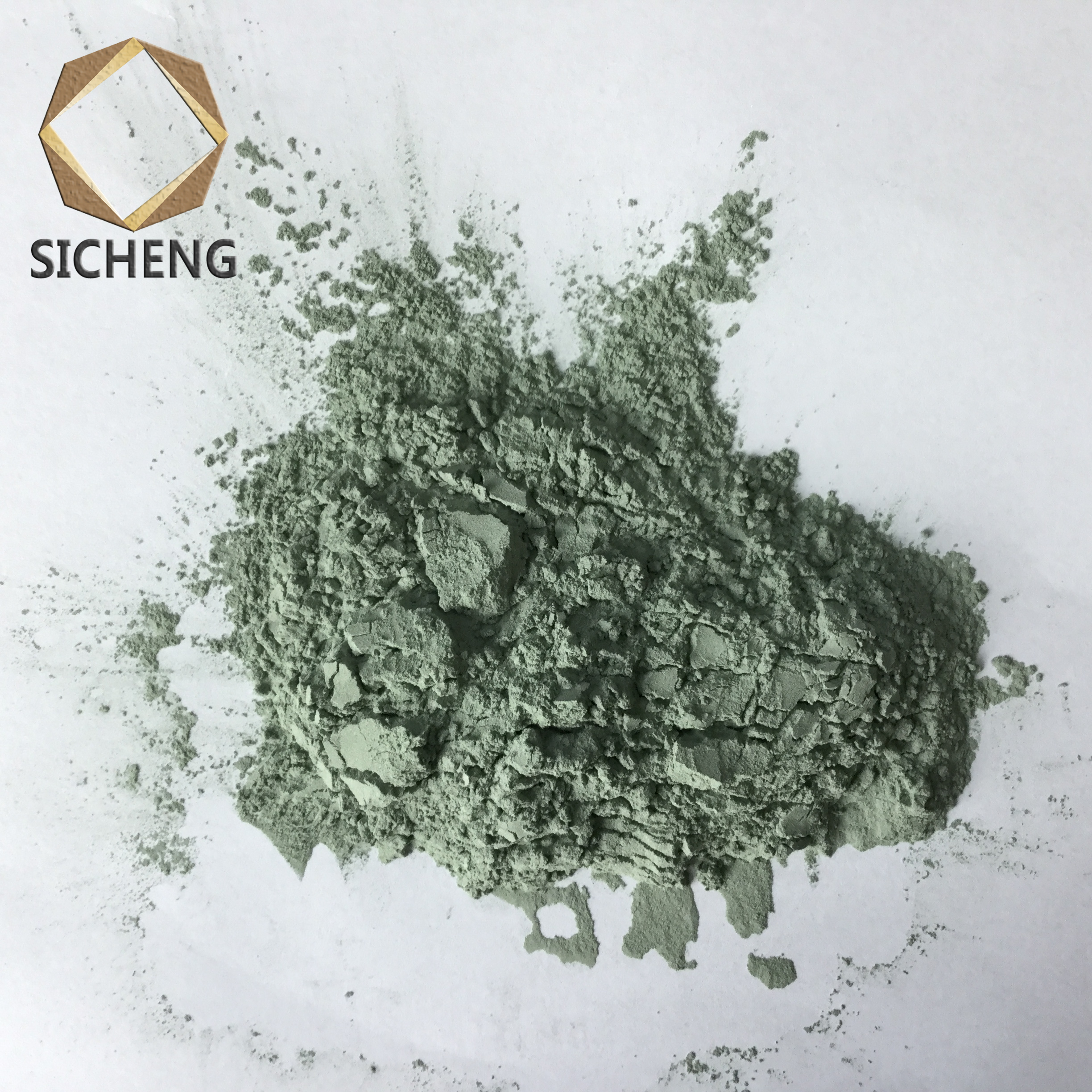

Silicon carbide powder for foam ceramic

Green Silicon Carbide is produced at high temperature in an electric resistance type furnace with quarts sand and petroleum coke. It is a synthetic brittle carborundum with high thermal conductivity and high strength which get no decrease in 1000℃( 7.5 times stronger than Alumina)

Green silicon carbide is characterized with extreme hardness (Mohs 9.4/2600 Knoop) which only rank after CBN and B4C.

| Mohs Hardness: | 9.5 |

| Vickers Hardness: | 3100-3400kg/mm2 |

| Specific Gravity: | 3.2g/cm3 |

| Bulk density(LPD): | 1.2-1.6 g/cm3 |

| Color: | Green |

| Particle shape: | Hexagonal |

| Melting Point: | Dissociated at about 2600 centigrade |

| Maximum service temperature: | 1900 centigrade |

| Friability | Friable |

| Thermal conductivity | 0.013 cal/cm2.sec (900°C) |

| Thermal expansion coefficient | 7-9 x10-6 /℃(0-1600°C) |

| TYPICAL CHEMICAL ANALYSIS(Silicon carbide powder for foam ceramic) | ||

| Chemical Content | F20-F220 | F230-F2000 |

| SiC | Min 99% | Min 98.5% |

| SiO2 | Max 0.50% | Max 0.70% |

| F,Si | Max 0.20% | Max 0.40% |

| Fe2O3 | Max 0.10% | Max 0.15% |

| F.C | Max 0.20% | Max 0.30% |

| L.O.I | Max 0.05% | Max 0.09% |

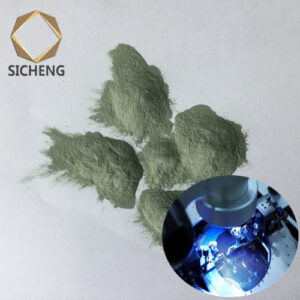

Green silicon carbide application:(Silicon carbide powder for foam ceramic)

1. Precision polishing for hard optical glass such as camera lens.

2. Abrasive blasting on hard metal CNB knife such as titanium alloy, carbide alloy, etc.

3. Polishing and grinding quartz glass.

4. Grinding hard stone, marbles, granite, etc.

5. Polishing PZT/ Piezoelectric ceramic.

6. Blasting copper and copper alloy.

7. Surface treatment on diamond tools.

8. Wire sawing.

9. Polishing jewelry such as diamond and cinnabar.

10. Grinding other thin brittle material precise component.

11. Anti-fire novel Nano Aerogel.

12. Fire insulation material such as sintered ceramics.

13. Teflon coating.

14. Fluorocarbon coating and paint.

15. High quality brake additives such as aero plane brakes.

16. Silicon carbide ceramic filler.

17. Polishing tools such as wet diamond polishing pad, PVC grinding disc, etc.

| Particle Size | Particle Distribution (µm) | |||

| Maximum Particle Size | Particle Size at d03 | Particle Size at d50 | Particle Size at d94 | |

| # 240 | ≤ 127 | ≤ 103 | 58.6 ± 3.0 | ≥ 40.0 |

| # 280 | ≤ 112 | ≤ 87.0 | 49.4 ± 3.0 | ≥ 33.0 |

| # 320 | ≤ 98.0 | ≤ 74.0 | 41.1 ± 2.5 | ≥ 27.0 |

| # 360 | ≤ 86.0 | ≤ 66.0 | 36.1 ± 2.0 | ≥ 23.0 |

| # 400 | ≤ 75.0 | ≤ 58.0 | 30.9 ± 2.0 | ≥ 20.0 |

| # 500 | ≤ 63.0 | ≤ 50.0 | 26.4 ± 2.0 | ≥ 16.0 |

| # 600 | ≤ 53.0 | ≤ 43.0 | 21.1 ± 1.5 | ≥ 13.0 |

| # 700 | ≤ 45.0 | ≤ 37.0 | 17.9 ± 1.3 | ≥ 11.0 |

| # 800 | ≤ 38.0 | ≤ 31.0 | 14.7 ± 1.0 | ≥ 9.00 |

| # 1000 | ≤ 32.0 | ≤ 27.0 | 11.9 ± 1.0 | ≥ 7.00 |

| # 1200 | ≤ 27.0 | ≤ 23.0 | 9.90 ± 0.80 | ≥ 5.50 |

| # 1500 | ≤ 23.0 | ≤ 20.0 | 8.40 ± 0.60 | ≥ 4.50 |

| # 2000 | ≤ 19.0 | ≤ 17.0 | 6.90 ± 0.60 | ≥ 4.00 |

| # 2500 | ≤ 16.0 | ≤ 14.0 | 5.60 ± 0.50 | ≥ 3.00 |

| # 3000 | ≤ 13.0 | ≤ 11.0 | 4.00 ± 0.50 | ≥ 2.00 |

| # 4000 | ≤ 11.0 | ≤ 8.00 | 3.00 ± 0.40 | ≥ 1.30 |

| # 6000 | ≤ 8.00 | ≤ 5.00 | 2.00 ± 0.40 | ≥ 0.80 |

| # 8000 | ≤ 6.00 | ≤ 3.5 | 1.20 ± 0.30 | ≥ 0.60(1) |

| # 10000 | 0.51~0.70 | |||