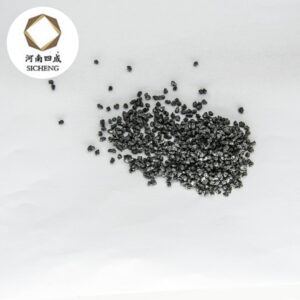

Black Silicon Carbide is produced by a process involving the electrochemical reaction of silica(SiO2) – in the form of quartz mixed with Carbon(C) in the form of raw petroleum coke. The stoichiometric mixture is reacted in an electrical resistance furnace at a temperature up to 2500℃ to yield high quality crystals. The process is large furnace technology with a graphite electrode in the furnace center. The large crystals are then segregated, crushed, cleaned of magnetic impurities in high intensity magnetic separators and classified into narrow size fractions to suit the end use. Dedicated lines produce products for different applications. The micro powder form silicon carbide from SiCheng Abrasives is with good size distribution, high purity, and low impurities.

Application

1.Abrasive materials

It is mainly used for grinding wheel, sandpaper, asphalt, grinding head, grinding paste and surface grinding and polishing of mono crystalline silicon, poly crystalline silicon and various devices in photo voltaic products.

2.Advanced Refractories

It can be used as metallurgical deoxidizer and high temperature resistant material to make high temperature kiln components and supporting parts.

3.Functional ceramics

Improving the quality of kiln products and shortening the period and is the ideal indirect materials for ceramic glaze baking and sintering, used for high temperature non-oxide ceramics and reactive sintering ceramics.

4.Nonferrous metal

used for Iron and steel industry, metallurgical mineral processing industry

Physical Properties

| Moh’s hardness | 9.15 |

| Melting point | 2250℃ |

| The service temperature | 1900℃ |

| Real density | 3.2-3.4g/cm3 |

Chemical composition

| SiC | ≥98% |

| F.C | ≤0.30% |

| H2O3 | ≤1% |

| SIO2 | ≤1% |

| Fe2O3 | ≤0.30% |

| Others | ≤0.02 |

Size

| Grains | 8# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220# |

| Powder | 240# 280# 320# 360# 400# 500# 600# 700# 800# 1000# 1200# 1500# 2000# 2500# 3000# 4000# 6000# 8000# |