Silicon carbide powder 5micron 6micron

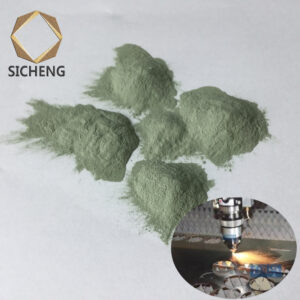

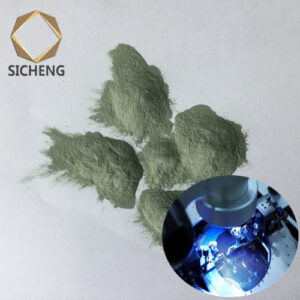

Green silicon carbide 9micron 10micron 11micron is suitable for polishing hard materials such as optical glass, marbles, ceramics, and other hard-fragile combined materials. It is produced from an acid & water washing process. There is very little Ferro residue with high cleanness. Green silicon carbide is characterized by its high hardness and powerful grinding ability. Green carborundum powder is an aggressive polishing powder on optical glass. The strength can retain even in high temperatures up to 1400 degrees.

Green silicon carbide application:(Silicon carbide powder 5micron 6micron )

1. Precision polishing for hard optical glass such as camera lens.

2. Abrasive blasting on hard metal CNB knife such as titanium alloy, carbide alloy, etc.

3. Polishing and grinding quartz glass.

4. Grinding hard stone, marbles, granite, etc.

5. Polishing PZT/ Piezoelectric ceramic.

6. Blasting copper and copper alloy.

7. Surface treatment on diamond tools.

8. Wire sawing.

9. Polishing jewelry such as diamond and cinnabar.

10. Grinding other thin brittle material precise component.

11. Anti-fire novel Nano Aerogel.

12. Fire insulation material such as sintered ceramics.

13. Teflon coating.

14. Fluorocarbon coating and paint.

15. High quality brake additives such as aero plane brakes.

16. Silicon carbide ceramic filler.

17. Polishing tools such as wet diamond polishing pad, PVC grinding disc, etc.

| Particle Size | Particle Distribution (µm) | |||

| Maximum Particle Size | Particle Size at d03 | Particle Size at d50 | Particle Size at d94 | |

| # 240 | ≤ 127 | ≤ 103 | 58.6 ± 3.0 | ≥ 40.0 |

| # 280 | ≤ 112 | ≤ 87.0 | 49.4 ± 3.0 | ≥ 33.0 |

| # 320 | ≤ 98.0 | ≤ 74.0 | 41.1 ± 2.5 | ≥ 27.0 |

| # 360 | ≤ 86.0 | ≤ 66.0 | 36.1 ± 2.0 | ≥ 23.0 |

| # 400 | ≤ 75.0 | ≤ 58.0 | 30.9 ± 2.0 | ≥ 20.0 |

| # 500 | ≤ 63.0 | ≤ 50.0 | 26.4 ± 2.0 | ≥ 16.0 |

| # 600 | ≤ 53.0 | ≤ 43.0 | 21.1 ± 1.5 | ≥ 13.0 |

| # 700 | ≤ 45.0 | ≤ 37.0 | 17.9 ± 1.3 | ≥ 11.0 |

| # 800 | ≤ 38.0 | ≤ 31.0 | 14.7 ± 1.0 | ≥ 9.00 |

| # 1000 | ≤ 32.0 | ≤ 27.0 | 11.9 ± 1.0 | ≥ 7.00 |

| # 1200 | ≤ 27.0 | ≤ 23.0 | 9.90 ± 0.80 | ≥ 5.50 |

| # 1500 | ≤ 23.0 | ≤ 20.0 | 8.40 ± 0.60 | ≥ 4.50 |

| # 2000 | ≤ 19.0 | ≤ 17.0 | 6.90 ± 0.60 | ≥ 4.00 |

| # 2500 | ≤ 16.0 | ≤ 14.0 | 5.60 ± 0.50 | ≥ 3.00 |

| # 3000 | ≤ 13.0 | ≤ 11.0 | 4.00 ± 0.50 | ≥ 2.00 |

| # 4000 | ≤ 11.0 | ≤ 8.00 | 3.00 ± 0.40 | ≥ 1.30 |

| # 6000 | ≤ 8.00 | ≤ 5.00 | 2.00 ± 0.40 | ≥ 0.80 |

| # 8000 | ≤ 6.00 | ≤ 3.5 | 1.20 ± 0.30 | ≥ 0.60(1) |

| # 10000 | 0.51~0.70 | |||