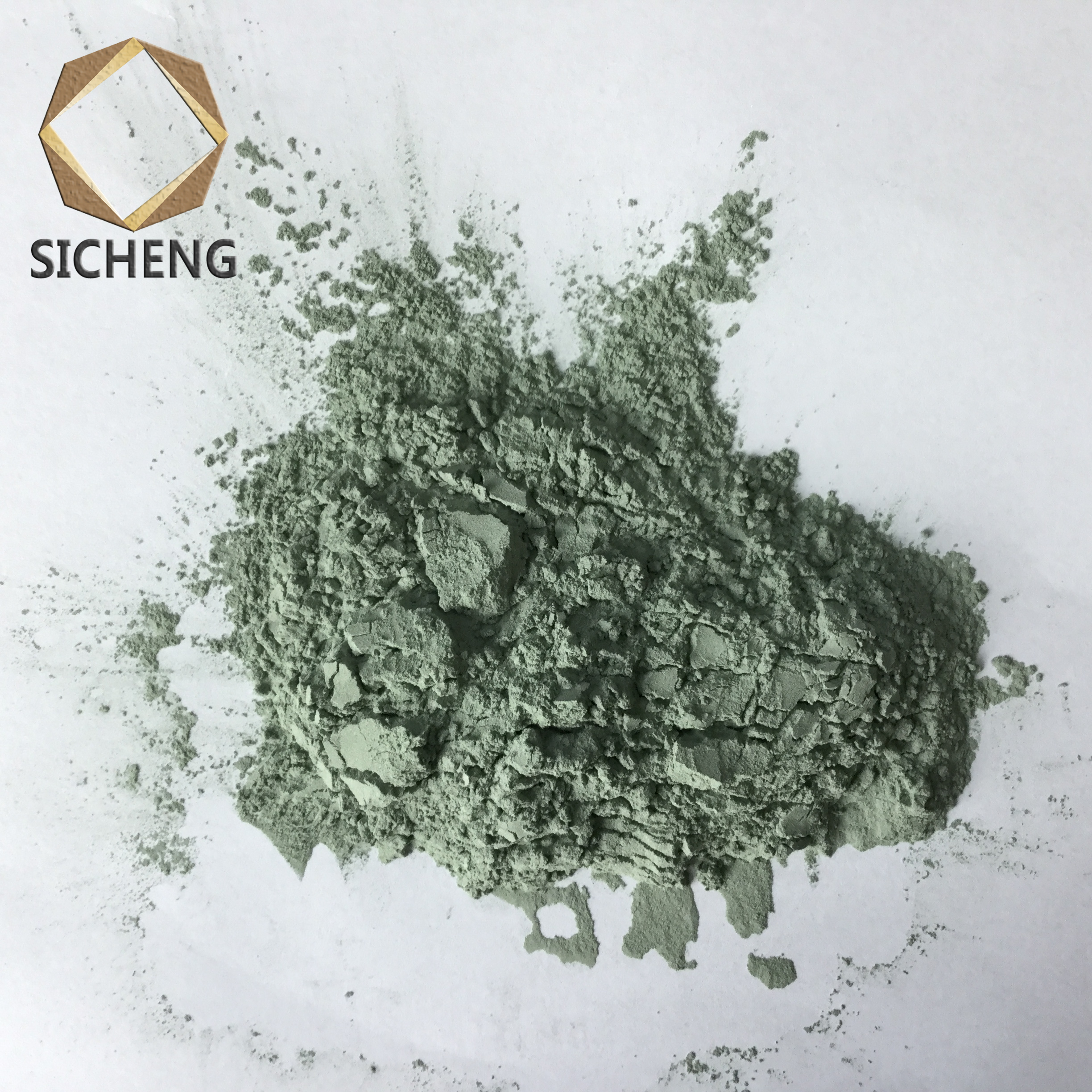

Green Silicon Carbide Powder 400#500#600#

Green silicon carbide SiC carborundum is produced at high temperature in an electric resistance type furnace with quarts sand and petroleum coke as its main raw materials. Its hardness is between fused alumina and synathetic diamond. Mechanical intensity of it is hig-her than fused alumina.it is brittle and sharp and has electrical and heat conductivity in some degree.

Grit | D50(um) | Grit | D50(um) |

#240 | 57.0±3.0 | #1000 | 11.5±1.0 |

#280 | 48.0±3.0 | #1200 | 9.5±0.8 |

#320 | 40.0±2.5 | #1500 | 8.0±0.6 |

#360 | 35.0±2.0 | #2000 | 6.7±0.6 |

#400 | 30.0±2.0 | #2500 | 5.5±0.5 |

#500 | 25.0±2.0 | #3000 | 4.0±0.5 |

#600 | 20.0±1.5 | #4000 | 3.0±0.4 |

#700 | 17.0±1.5 | #6000 | 2.0±0.4 |

#800 | 14.0±1.0 | #8000 | 1.2±0.3 |

•Abrasive and Grinding Applications

Used to manufacture grinding tools like grinding wheels and sandpapers, suitable for grinding and polishing hard materials such as cemented carbide, glass, and ceramics.

•High – tech Ceramic Components

Serves as a raw material for producing wear – resistant and high – temperature – resistant ceramic parts, applied in aerospace, electronic devices, and other advanced fields.

•Semiconductor and Electronics Industry

Utilized for cutting and grinding semiconductor wafers to meet the high – precision processing requirements in the manufacturing of sophisticated electronic components.

•Refractory Materials Production

Fabricated into high – temperature – resistant refractory bricks and coatings, used as lining protection in high – temperature environments like metallurgical furnaces and kilns.

•Wear and Corrosion – Resistant Coatings

Forms wear – resistant coatings through spraying or sintering processes to enhance the corrosion and wear resistance of mechanical components (e.g., pump impellers, pipelines).

•Jewelry Processing and Polishing

Acts as a fine abrasive for cutting and polishing gemstones to achieve high – gloss surface treatment of jewelry.

•Metal Surface Treatment

Employed in sandblasting processes to remove oxide scales, rust, or coatings from metal workpieces, achieving surface cleaning and roughening.

•Abrasive Additives for Grinding Tools

Mixed with other abrasives to optimize the grinding efficiency and service life of grinding tools, suitable for machining complex materials.