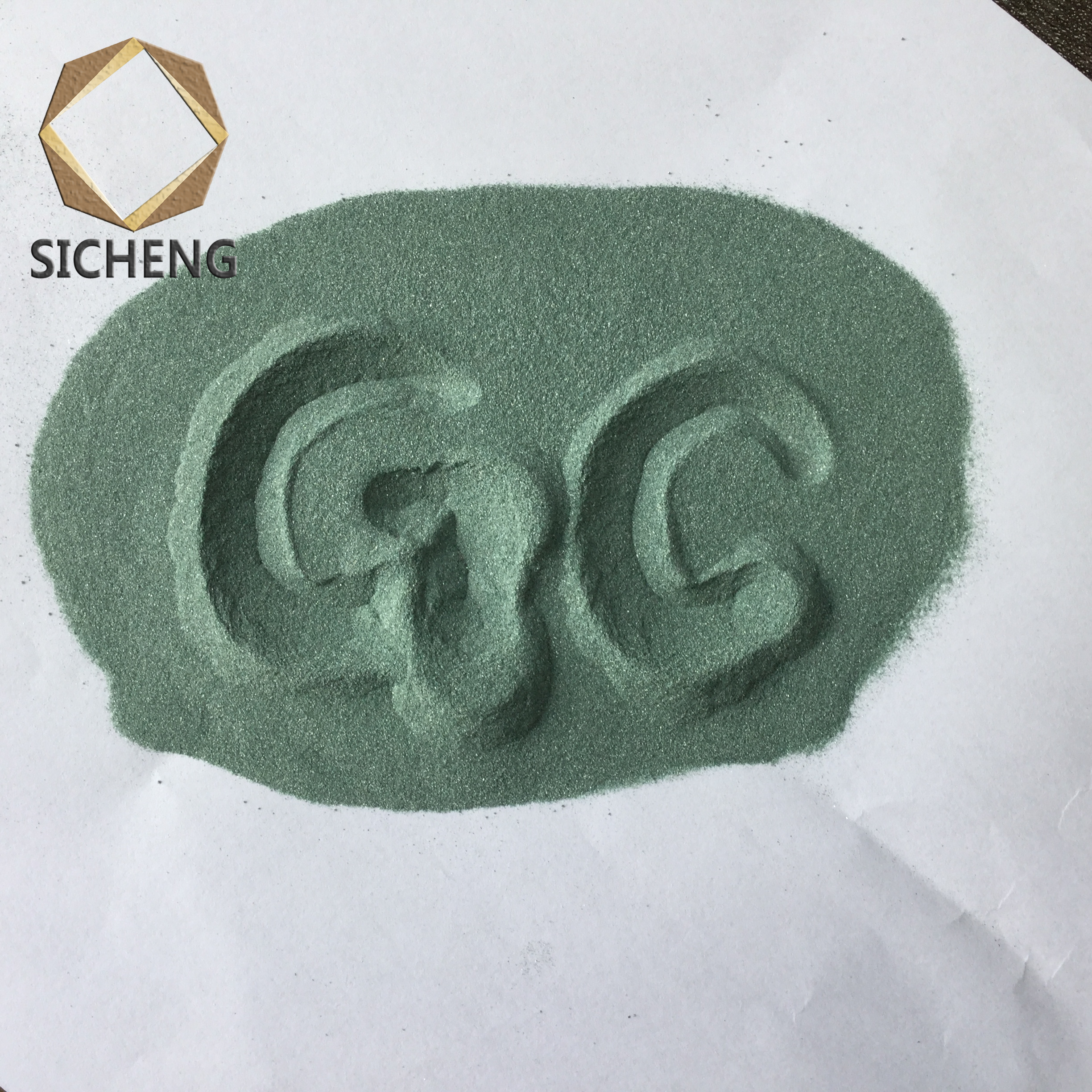

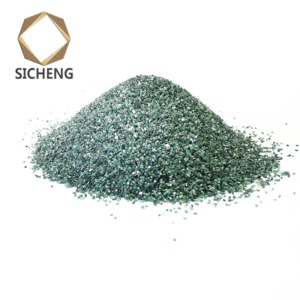

Green Silicon Carbide F24 F36 F40 F46 Green SiC

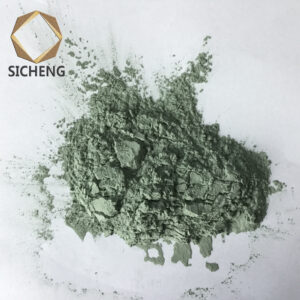

Green Silicon Carbide F24 F36 F40 F46 Green SiC is a very hard abrasive material with uniform particle size distribution. The hardness of it only ranks after diamond and B4C, and it is harder than black silicon carbide. So it is suitable for grinding a large range of hard materials such as titanium alloy, marble, carbide alloy, optical glasses, ceramics, etc.

On the other hand, green silicon carbide has extraordinary features such as high chemical stability, low thermal expansion rate, it is suitable for heat resistance & corrosion resistance coatings, paints, and other construction products.

Technical Data Sheets

| Item | Grit | Chemical Composition (%) | Size Distribution (%) | Bulk Density | |||||||||||

| SiC | Fe2O3 | F.C. | D3 | D50 | D94 | ||||||||||

| Macro Grits | F24 | 99.00% | 0.15% | 0.15% | / | / | / | 1.50-1.60 | |||||||

| F30 | 99.00% | 0.15% | 0.15% | / | / | / | 1.50-1.60 | ||||||||

| F36 | 99.00% | 0.15% | 0.15% | / | / | / | 1.50-1.60 | ||||||||

| F40 | 99.00% | 0.15% | 0.15% | / | / | / | 1.50-1.60 | ||||||||

| F46 | 99.00% | 0.15% | 0.15% | / | / | / | 1.48-1.58 | ||||||||

| F54 | 99.00% | 0.15% | 0.15% | / | / | / | 1.48-1.58 | ||||||||

| F60 | 99.00% | 0.15% | 0.15% | / | / | / | 1.48-1.58 | ||||||||

| F70 | 99.00% | 0.15% | 0.15% | / | / | / | 1.46-1.56 | ||||||||

| F80 | 99.00% | 0.15% | 0.15% | / | / | / | 1.46-1.56 | ||||||||

| F90 | 99.00% | 0.15% | 0.15% | / | / | / | 1.44-1.54 | ||||||||

| F100 | 99.00% | 0.15% | 0.15% | / | / | / | 1.40-1.50 | ||||||||

| F120 | 99.00% | 0.15% | 0.15% | / | / | / | 1.38-1.48 | ||||||||

| F150 | 98.50% | 0.20% | 0.20% | / | / | / | 1.38-1.48 | ||||||||

| F180 | 98.50% | 0.20% | 0.20% | / | / | / | 1.30-1.40 | ||||||||

| F220 | 98.50% | 0.20% | 0.20% | / | / | / | 1.30-1.40 | ||||||||

| Micro Powder | F240 | ≥99 | ≤0.15 | ≤0.15 | ≤70 | 44.5±2.0 | ≥28 | 1.38 | |||||||

| F280 | ≥99 | ≤0.15 | ≤0.15 | ≤59 | 36.5±1.5 | ≥22 | 1.31 | ||||||||

| F320 | ≥99 | ≤0.15 | ≤0.15 | ≤49 | 29.2±1.5 | ≥16.5 | 1.28 | ||||||||

| F360 | ≥99 | ≤0.15 | ≤0.15 | ≤40 | 22.8±1.5 | ≥12 | 1.26 | ||||||||

| F400 | ≥99 | ≤0.15 | ≤0.15 | ≤32 | 17.3±1.0 | ≥8 | 1.16 | ||||||||

| F500 | ≥99 | ≤0.15 | ≤0.15 | ≤25 | 12.8±1.0 | ≥5 | 0.98 | ||||||||

| F600 | ≥99 | ≤0.15 | ≤0.15 | ≤19 | 9.3±1.0 | ≥3 | / | ||||||||

| F800 | ≥98.5 | ≤0.15 | ≤0.15 | ≤14 | 6.5±1.0 | ≥2 | / | ||||||||

| F1000 | ≥97 | ≤0.15 | ≤0.15 | ≤10 | 4.5±0.8 | ≥1 | / | ||||||||

| F1200 | ≥96.5 | ≤0.15 | ≤0.15 | ≤7 | 3.0±0.5 | ≥0.8 | / | ||||||||

Green silicon carbide (SiC) is a high-hardness, sharp-edged abrasive material with excellent thermal conductivity and chemical stability. Due to its unique properties, it finds applications in various industries. Here are some key applications:

1. Abrasive Applications

Grinding Wheels & Cutting Tools: Used for grinding hard materials like carbide, ceramics, glass, and titanium.

Sandblasting & Polishing: Effective for surface preparation and finishing of metals, stone, and composites.

Lapping & Honing: Used in precision finishing of mechanical parts.

2. Refractory & Ceramic Industry

High-Temperature Linings: Added to refractory materials to improve thermal shock resistance in furnaces and kilns.

Ceramic Reinforcement: Enhances the strength and wear resistance of ceramic components.

3. Metallurgical Applications

Deoxidizer: Used in steelmaking to remove oxygen and improve metal quality.

Silicon Carbide Bricks: Used in blast furnaces and foundries for high thermal conductivity.

4. Semiconductor & Electronics

High-Power Electronics: Used in diodes, MOSFETs, and other devices due to its wide bandgap.

LED Substrates: Acts as a base material for high-brightness LEDs.

5. Automotive & Aerospace

Brake Discs & Pads: Used in high-performance vehicles for better heat dissipation.

Turbine Components: Reinforces parts exposed to extreme temperatures.

6. Wear-Resistant Coatings

Applied as a coating on industrial machinery, pumps, and valves to extend lifespan.

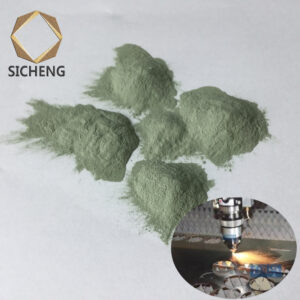

7. Water Jet Cutting

Mixed with water for precision cutting of metals, stone, and composites.

8. Solar & Renewable Energy

Used in photovoltaic cells and as a crucible material for solar silicon production.

9. Chemical & Anti-Corrosion Applications

Used in seals, nozzles, and components exposed to corrosive environments.

10. 3D Printing & Advanced Composites

Reinforces polymer and metal matrices for high-strength 3D-printed parts.

Advantages Over Black Silicon Carbide

Higher purity (≥97% SiC).

Sharper grains, making it more effective for precision grinding.

Better thermal and electrical properties.