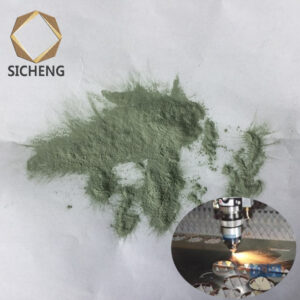

Green Silicon Carbide f1000 Silicon Carbide Powder

Green Silicon carbide (SiC), also known as carborundum, is a compound of silicon and carbon with chemical formula SiC. It occurs in nature as the extremely rare mineral moissanite. Synthetic silicon carbide powder has been mass-produced since 1893 for use as an abrasive. Grains of silicon carbide can be bonded together by sintering to form very hard ceramics that are widely used in applications requiring high endurance, such as car brakes, car clutches and ceramic plates in bulletproof vests. Electronic applications of silicon carbide such as light-emitting diodes (LEDs) and detectors in early radios were first demonstrated around 1907. SiC is used in semiconductor electronics devices that operate at high temperatures or high voltages, or both. Large single crystals of silicon carbide can be grown by the Lely method; they can be cut into gems known as synthetic moissanite. Silicon carbide with high surface area can be produced from SiO2 contained in plant material.

| Particle Size | Particle Distribution (µm) | |||

| Maximum Particle Size | Particle Size at d03 | Particle Size at d50 | Particle Size at d94 | |

| # 240 | ≤ 127 | ≤ 103 | 58.6 ± 3.0 | ≥ 40.0 |

| # 280 | ≤ 112 | ≤ 87.0 | 49.4 ± 3.0 | ≥ 33.0 |

| # 320 | ≤ 98.0 | ≤ 74.0 | 41.1 ± 2.5 | ≥ 27.0 |

| # 360 | ≤ 86.0 | ≤ 66.0 | 36.1 ± 2.0 | ≥ 23.0 |

| # 400 | ≤ 75.0 | ≤ 58.0 | 30.9 ± 2.0 | ≥ 20.0 |

| # 500 | ≤ 63.0 | ≤ 50.0 | 26.4 ± 2.0 | ≥ 16.0 |

| # 600 | ≤ 53.0 | ≤ 43.0 | 21.1 ± 1.5 | ≥ 13.0 |

| # 700 | ≤ 45.0 | ≤ 37.0 | 17.9 ± 1.3 | ≥ 11.0 |

| # 800 | ≤ 38.0 | ≤ 31.0 | 14.7 ± 1.0 | ≥ 9.00 |

| # 1000 | ≤ 32.0 | ≤ 27.0 | 11.9 ± 1.0 | ≥ 7.00 |

| # 1200 | ≤ 27.0 | ≤ 23.0 | 9.90 ± 0.80 | ≥ 5.50 |

| # 1500 | ≤ 23.0 | ≤ 20.0 | 8.40 ± 0.60 | ≥ 4.50 |

| # 2000 | ≤ 19.0 | ≤ 17.0 | 6.90 ± 0.60 | ≥ 4.00 |

| # 2500 | ≤ 16.0 | ≤ 14.0 | 5.60 ± 0.50 | ≥ 3.00 |

| # 3000 | ≤ 13.0 | ≤ 11.0 | 4.00 ± 0.50 | ≥ 2.00 |

| # 4000 | ≤ 11.0 | ≤ 8.00 | 3.00 ± 0.40 | ≥ 1.30 |

| # 6000 | ≤ 8.00 | ≤ 5.00 | 2.00 ± 0.40 | ≥ 0.80 |

| # 8000 | ≤ 6.00 | ≤ 3.5 | 1.20 ± 0.30 | ≥ 0.60(1) |

| # 10000 | 0.51~0.70 | |||

Applications of Green silicon carbide

- Precision polishing for hard optical glass such as camera lens.

- Abrasive blasting on hard metal CNB knife such as titanium alloy, carbide alloy, etc.

- Polishing and grinding quartz glass.

- Grinding hard stone, marbles, granite, etc.

- Polishing PZT/ Piezoelectric ceramic.

- Blasting copper and copper alloy.

- Surface treatment on diamond tools.

- Wire sawing.

- Polishing jewelry such as diamond and cinnabar.

- Grinding other thin brittle material precise component.

- Anti-fire novel Nano Aerogel.

- Fire insulation material such as sintered ceramics.

- Teflon coating.

- Fluorocarbon coating and paint.

- High-quality brake additives such as airplane brakes.

- Silicon carbide ceramic filler.

- Polishing tools such as wet diamond polishing pad, PVC grinding disc, etc.