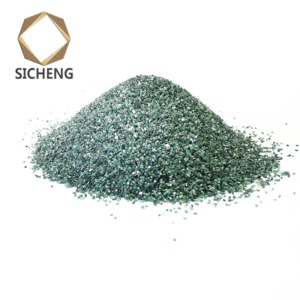

F60 Green Silicon Carbide for Ceramic Grinding Wheel

Green Silicon Carbide’s crystalline form have high purity and hardness. Due to its sharp-edged characteristic, green silicon carbide is exceptionally fit for abrasive applications where the removal of hard material is needed.

| Mohs Hardness: | 9.5 |

| Vickers Hardness: | 3100-3400kg/mm2 |

| Specific Gravity: | 3.2g/cm3 |

| Bulk density(LPD): | 1.2-1.6 g/cm3 |

| Color: | Green |

| Particle shape: | Hexagonal |

| Melting Point: | Dissociated at about 2600 centigrade |

| Maximum service temperature: | 1900 centigrade |

| Friability | Friable |

| Thermal conductivity | 0.013 cal/cm2.sec (900°C) |

| Thermal expansion coefficient | 7-9 x10-6 /℃(0-1600°C) |

| TYPICAL CHEMICAL ANALYSIS F60 Green Silicon Carbide for Ceramic Grinding Wheel | ||

| Chemical Content | F20-F220 | F230-F2000 |

| SiC | Min 99% | Min 98.5% |

| SiO2 | Max 0.50% | Max 0.70% |

| F,Si | Max 0.20% | Max 0.40% |

| Fe2O3 | Max 0.10% | Max 0.15% |

| F.C | Max 0.20% | Max 0.30% |

| L.O.I | Max 0.05% | Max 0.09% |

•Abrasive and Grinding Applications F60 Green Silicon Carbide for Ceramic Grinding Wheel

Used to manufacture grinding tools like grinding wheels and sandpapers, suitable for grinding and polishing hard materials such as cemented carbide, glass, and ceramics.

•High – tech Ceramic Components

Serves as a raw material for producing wear – resistant and high – temperature – resistant ceramic parts, applied in aerospace, electronic devices, and other advanced fields.

•Semiconductor and Electronics Industry

Utilized for cutting and grinding semiconductor wafers to meet the high – precision processing requirements in the manufacturing of sophisticated electronic components.

•Refractory Materials Production

Fabricated into high – temperature – resistant refractory bricks and coatings, used as lining protection in high – temperature environments like metallurgical furnaces and kilns.

•Wear and Corrosion – Resistant Coatings

Forms wear – resistant coatings through spraying or sintering processes to enhance the corrosion and wear resistance of mechanical components (e.g., pump impellers, pipelines).

•Jewelry Processing and Polishing

Acts as a fine abrasive for cutting and polishing gemstones to achieve high – gloss surface treatment of jewelry.

•Metal Surface Treatment

Employed in sandblasting processes to remove oxide scales, rust, or coatings from metal workpieces, achieving surface cleaning and roughening.

•Abrasive Additives for Grinding Tools

Mixed with other abrasives to optimize the grinding efficiency and service life of grinding tools, suitable for machining complex materials.