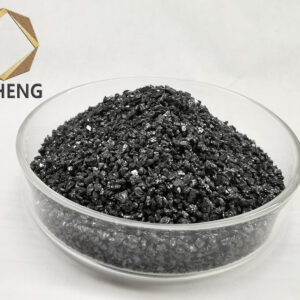

Black emery F46 F54 F60 F80 silicon carbide

Black emery F24 F36 silicon carbide grits is an artificial abrasive made of carbonaceous materials and siliceous materials through high-temperature smelting in a large arc furnace. The carbonaceous material is petroleum coke or coal coke. And the siliceous material always goes quartz sand. At the same time, the smelting process will also add wood chips, salt, and other additives.

The purity of the silicon carbide of the first-grade black silicon carbide is more than 98%. The color is shiny, and the reflection shows multicolored colors. Generally, the higher the purity of silicon carbide, the better its physical and chemical properties. The hardness of black silicon carbide is slightly lower than that of green silicon carbide, with a Mohs hardness of 9.2-9.3. Black silicon carbide grit is produced by crushing, washing, screening, magnetic separation, and other processes from first-grade silicon carbide blocks. It has the characteristics of high purity, high cleanliness, high packing density, and low impurities.

| Grit | 1 | 2 | 3 | 3 and 4 | 5 | Q5max,% | ||||

| W1,um | Q1,% | W2,um | Q2max,% | W3,um | Q3min,% | W4,um | Q3+Q4min,% | W5,um | ||

| F14 | 2360 | 0 | 1700 | 20 | 1400 | 45 | 1180 | 70 | 1000 | 3 |

| F16 | 2000 | 0 | 1400 | 20 | 1180 | 45 | 1000 | 70 | 820 | 3 |

| F20 | 1700 | 0 | 1180 | 20 | 1000 | 45 | 850 | 70 | 710 | 3 |

| F22 | 1400 | 0 | 1000 | 20 | 850 | 45 | 710 | 70 | 600 | 3 |

| F24 | 1180 | 0 | 850 | 25 | 710 | 45 | 600 | 65 | 500 | 3 |

| F30 | 1000 | 0 | 710 | 25 | 600 | 45 | 500 | 65 | 425 | 3 |

| F36 | 850 | 0 | 600 | 25 | 500 | 45 | 425 | 65 | 355 | 3 |

| F40 | 710 | 0 | 500 | 30 | 425 | 40 | 355 | 65 | 300 | 3 |

| F46 | 600 | 0 | 425 | 30 | 355 | 40 | 300 | 65 | 250 | 3 |

| F54 | 500 | 0 | 355 | 30 | 300 | 40 | 250 | 65 | 212 | 3 |

| F60 | 425 | 0 | 300 | 30 | 250 | 40 | 212 | 65 | 180 | 3 |

| F70 | 355 | 0 | 250 | 25 | 212 | 40 | 180 | 65 | 150 | 3 |

| F80 | 300 | 0 | 212 | 25 | 180 | 40 | 150 | 65 | 125 | 3 |

| F90 | 250 | 0 | 180 | 20 | 150 | 40 | 125 | 65 | 106 | 3 |

| F100 | 212 | 0 | 150 | 20 | 125 | 40 | 106 | 65 | 90 | 3 |

| F120 | 180 | 0 | 125 | 20 | 106 | 40 | 90 | 65 | 75 | 3 |

| F150 | 150 | 0 | 106 | 15 | 90 | 40 | 75 | 65 | 63 | 3 |

| F180 | 125 | 0 | 90 | 15 | 75 | * | 63 | 40 | 53 | * |

| F220 | 106 | 0 | 75 | 15 | 63 | * | 53 | 40 | 45 | * |

Typical physical properties of Black emery F46 F54 F60 F80 silicon carbide

| Hardness: | Mohs:9.2 |

| Melting Point: | dissociated at about 2300 °C |

| Maximum service temperature: | 1900℃ |

| Specific Gravity: | 3.2-3.45 g/cm3 |

| Bulk density(LPD): | 1.2-1.6 g/cm3 |

| Color: | Black |

| Particle shape: | Hexagonal |

| Modulus of Elasticity | 58-65×106 psi |

| Coefficient of Thermal Expansion | 3.9-4.5 x10-6/ ℃ |

| Thermal Conductivity | 71-130 W/MK |

Typical physical properties of Black emery F46 F54 F60 F80 silicon carbide

| SiC | 98.75% |

| Fe2O3 | 0.18% |

| F.C | 0.14% |

| Magnetic content | 0.011% |

Product Feature of Black emery F46 F54 F60 F80 silicon carbide

- Good oxidation resistance and chemical stability at high temperatures.

- High hardness with Mohs 9.2-9.3. Even at 2000℃, it’s still getting high strength.

- Excellent toughness.

- Low thermal conductivity. So it can resistant to thermal shock.

- High purity min SiC content is 98.5%.

- High bulk density.

- Black silicon carbide grit is washed by water before the milling process, so there are few impurities.

Application of Black emery F46 F54 F60 F80 silicon carbide

Fiber Sanding disc

Sintered silicon carbide ceramic

black silicon carbide grinding wheel such as cup grinding wheel

Sanding sheet

Semi flex grinding disc for marble, granite.

Other abrasive tools.