Black Silicon Carbide Sizes Range: Precision-Graded for Diverse Industrial Applications

Black silicon carbide, renowned for its high hardness, thermal stability, and exceptional abrasive properties, is available in a comprehensive range of sizes to meet the specific needs of various industries. Below is a detailed overview of our standardized size classifications, designed to ensure optimal performance in applications from grinding and polishing to blasting and refractories.

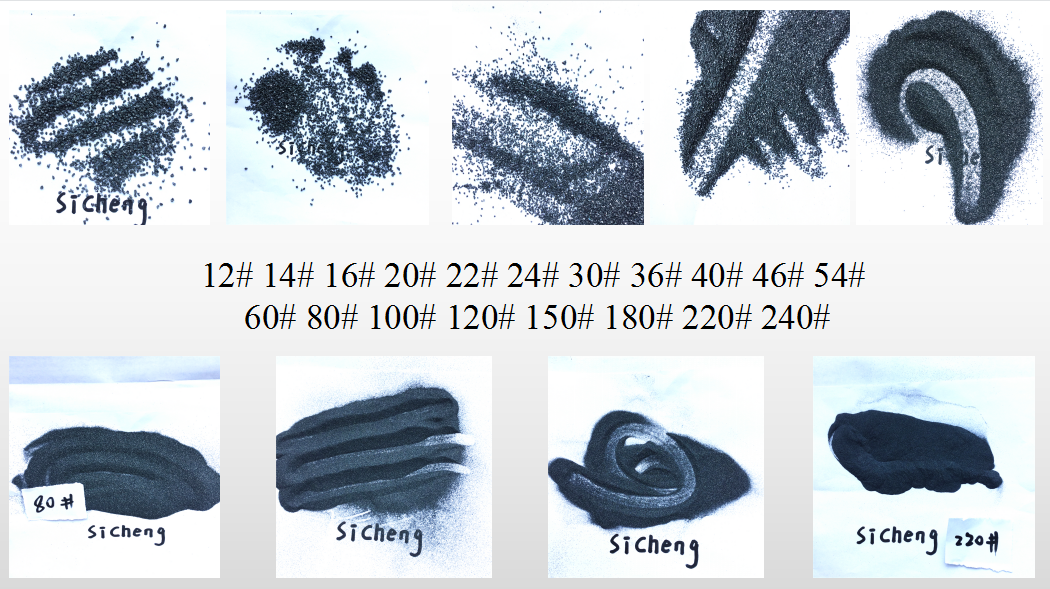

1. Granular Sizes: Coarse to Medium Grades

Ideal for heavy-duty abrasive tasks and structural applications, our granular black silicon carbide is graded to balance cutting efficiency with material durability.

- Coarse Granules (16#–46#):

- 16# / 1180μm: Suited for rough grinding of metals, ceramics, and stone, such as shaping granite slabs or deburring cast iron components.

- 24# / 850μm: Commonly used in sandblasting equipment for removing rust, paint, or scale from large surfaces (e.g., ship hulls, steel structures).

- 36# / 600μm & 46# / 425μm: Effective in wheel abrasives for foundry work and metal blank processing, offering a balance between material removal rate and surface finish.

- Medium Granules (60#–100#):

- 60# / 250μm & 80# / 180μm: Perfect for precision grinding of tools (e.g., drills, saw blades) and preparing surfaces for plating or coating.

- 100# / 150μm: Used in bonded abrasives for woodworking and in the production of abrasive paper for medium-finish sanding.

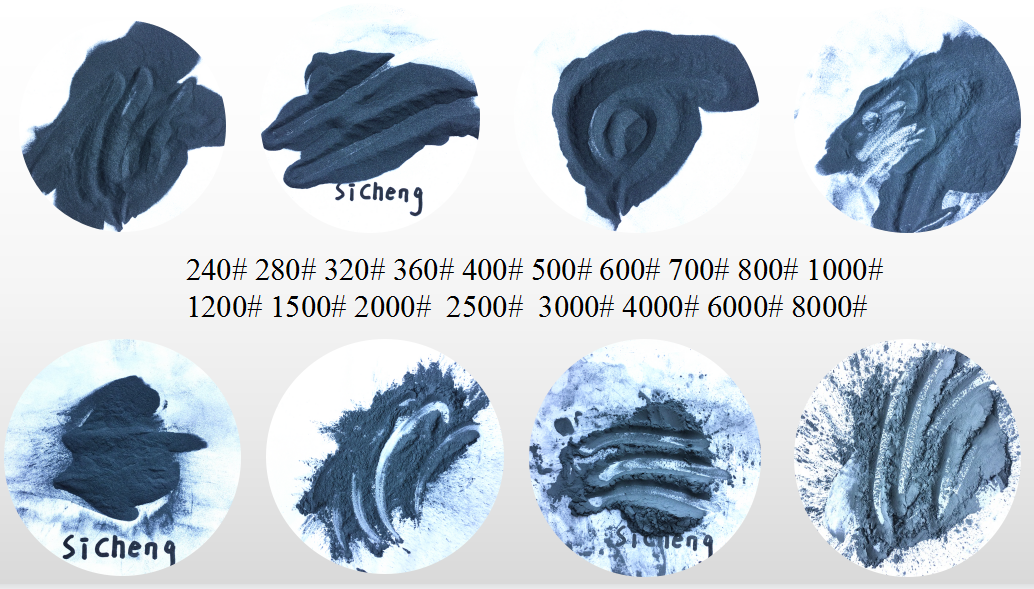

2. Powder Sizes: Fine to Ultra-Fine Grades

Engineered for applications requiring (fine) particle control, such as lapping, polishing, and high-tech manufacturing.

- Fine Powders (120#–325#):

- 120# / 125μm & 150# / 106μm: Used in lapping compounds for precision components like bearings, seals, and optical lenses.

- 220# / 63μm & 240# / 53μm: Suitable for polishing non-ferrous metals and ceramics to achieve a smooth, matte finish.

- 325# / 45μm: Critical in the production of grinding wheels for super-finishing and in abrasive slurries for semiconductor wafer processing.

- Ultra-Fine Powders (Micron Sizes):

- Micron 25 / 25μm & Micron 15 / 15μm: Used in high-precision lapping of magnetic heads, carbide tools, and medical implants.

- Micron 10 / 10μm & Micron 5 / 5μm: Ideal for polishing optical glass, gemstones, and microelectronic components to a mirror-like surface.

- Micron 1 / 1μm & Below: Employed in advanced ceramic sintering and as a reinforcing filler in composite materials for aerospace and automotive industries.

3. Custom Size Specifications

Understanding that unique projects demand tailored solutions, we also offer:

- Custom grading to meet specific particle size distributions (PSD) for specialized applications.

- Strict quality control to ensure consistency in particle shape, hardness, and chemical purity across all sizes.

- Bulk packaging options (25kg bags, 1-ton supersacks, or container loads) to accommodate large-scale industrial needs.

Applications by Size Range

| Size Category | Particle Range | Typical Uses |

|---|---|---|

| Coarse Granules | 16#–46# (1180–425μm) | Sandblasting, rough grinding, foundry |

| Medium Granules | 60#–100# (250–150μm) | Tool sharpening, surface preparation |

| Fine Powders | 120#–325# (125–45μm) | Lapping, polishing, abrasive tools |

| Ultra-Fine Powders | Micron 25–Micron 1 | Precision engineering, semiconductor |

Why Choose Our Black Silicon Carbide?

- Purity: 98%+ SiC content ensures minimal impurities and maximum abrasive performance.

- Uniformity: Tight size tolerances guarantee consistent results across batches.

- Versatility: From heavy-duty industrial processes to microscale manufacturing, our size range covers it all.